Okay, except for one kit I built, I've never done fins through the wall before. It's a stronger joint, a method used throughout mid-power and high-power rocketry out of necessity. When you're launching, say, 800 newton-seconds of impulse, there's a lot more stress on everything than when you're launching a rocket on 10 newton-seconds.

The E-30 Aerotech composite I launch Floyd on, for a frame of reference, is a 40 newton-second motor. A newton-second is the impulse required to move a kilogram one meter in one second. Which is metric, and I know that sucks, but rocket scientists are famously bad at resisting commie plots such as the metric system.

Yes, I'm one of those guys like the character in Orwell's 1984 who thinks a beer tastes different if measured in half liters instead of pints. Because I can't visualize a half liter, and it sounds stupid anyway. Imagine the poverty of the language if we really went metric! Who wants to read The Green Kilometer? Or watch The Longest Meter? And what would the Wild West look like if those guys were running around in 37.83 Liter hats*?

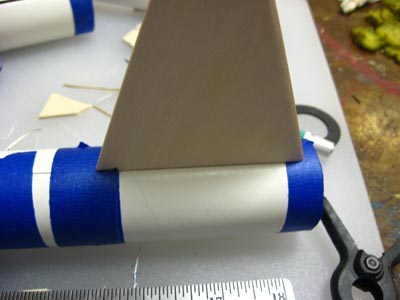

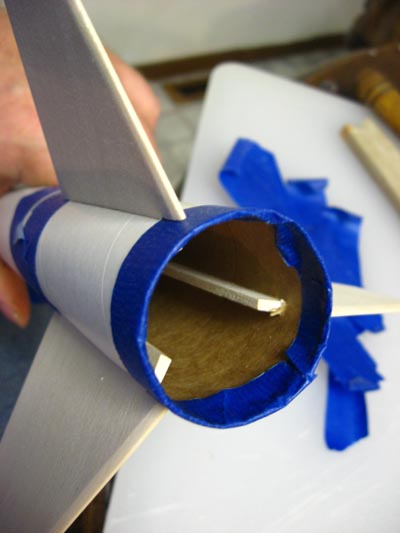

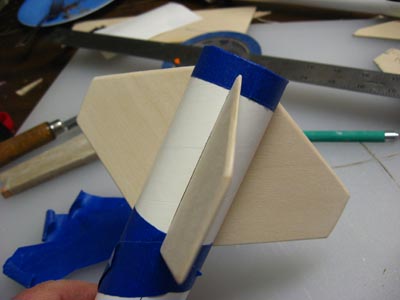

But back to the whole thrust thing: get into the high power rockets and it's not hard to have a motor that would literally leave its fins behind. The stress at deployment of the parachute is greater, too. So if you don't want the fins to leave the party, you go through the wall and mount the fins to the motor tube (or otherwise to an interior tube). This gives you two points of attachment for the fins, a much stronger relationship.

I'm not flying high power rockets, of course. I might go for my Level I certification this year, but that's only a 'might.' I'm more likely to see if I can design and build a scratch-built mid-power that breaks the sound barrier. And in any case, the main emphasis is still going to be park flyers because launching with my daughters is a huge part of the hobby for me. I still think a long-term goal is to put a personal satellite in orbit, because anything the Soviets could do in the 1950s, a middle-class American should be able to do now, but it's still important that most of my rockets are stuff I can throw in the trunk if the winds are calm of a summer evening and take the girls to harass the soccer cops.

So this latest, yet to be named, rocket is a park flier with a difference. He's got through the wall fins because it's better construction. The stoutest motor his mount will accept is an F21 composite, but he'll fly well on Estes D and E motors. Even the C11. Gets to maybe 380 feet on a C11, over 2500 feet on an F21. The latter gets upwards of 689 feet per second maximum velocity, which is something like 470 mph, which is to say subsonic but wicked fast.

And with the through-the-wall fins, epoxied to the motor tube and to the body tube, the occasional hard landing should be more survivable. I saw a guy launching a similar rocket, about half the length, but otherwise the same, on D12's with streamer recovery. He even took a landing on the blacktop. The landing he took, we had all sighed our sympathies on what was surely a retired rocket, but he flew again that day. Basswood fins through the body to the motor tube, he explained. Made a believer out of me.

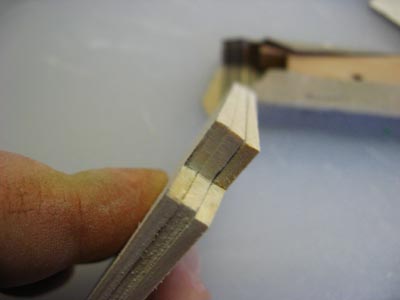

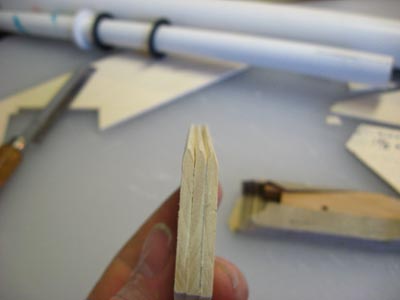

I also sanded the fins, best as I could, to be streamlined for minimal drag. A rounded, bullnose to the front, and a sharp, knife-edge taper at the side and rear. To do this, I stack the fins and sand the trail edge at what I guess is about a 20º angle (the distance to clear my guitar-pickin' thumb nail from the fin. Same for the outside edge. The lead edge gets a rounded sand. By rearranging the order in the stack, I can see when I've got the overall shape about right.

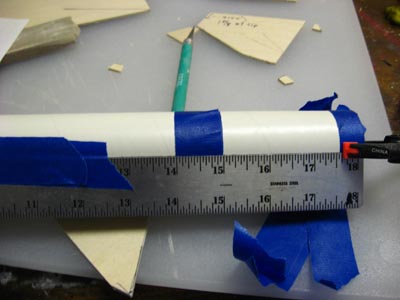

The fin slots are tricky to cut by hand, but with some tape and a straight edge, not impossible. Test fitting the fins, even without the motor tube and centering rings, they align pretty neatly and seem to want to stay where I want them to be... Balsa Machining will laser-cut my tubes for me, but I didn't know that when I bought the body tube stock I'm presently working through. Some of my designs, as I get them more refined, I may be able to order the component parts as a more or less 'custom' kit, with the worst of the precision work done for me. Or maybe I'll decide I don't want that stuff done for me anyway.

And then, by the time I get through this batch of tubing, I may decide I want to buy some Giant Leap stuff and start doing more fiberglass based construction.

I still need to epoxy everything together. And, of course, I have to come up with a good stupid name...

*For real, that's what a ten gallon hat would have to be called. And soccer is not 'football.'

1 comment:

Football is football and soccer is not football. Which came first and where i.e. in which language? Q.E.D.

It's got something to do with science. Cool blog.

Post a Comment